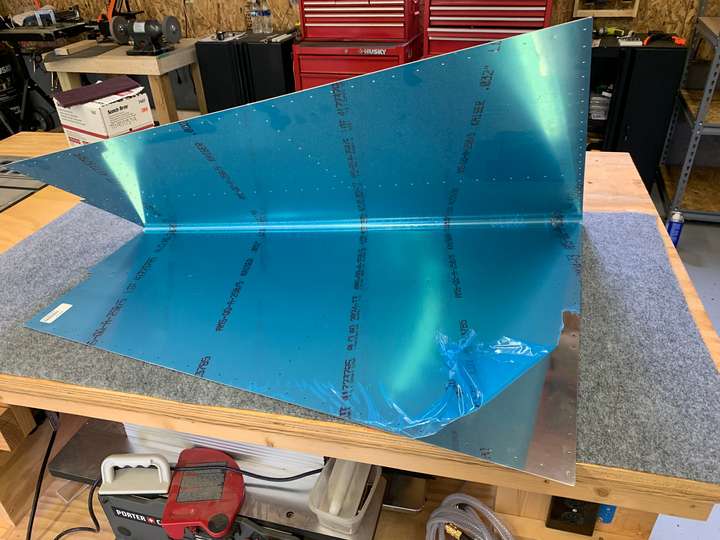

Priming Empennage Parts

All the parts for the tailkit section have been deburred and re-labeled, so today we spent about 8 hours preparing and priming the parts. We decided to use PreKote and ScotchBrite pads to lightly scuff and clean the aluminum to ensure the primer had good adhesion. The builder community seems mixed on whether or not the PreKote step is necessary if you are using the P60G2 industrial wash primer from Sherwin-Williams. We decided to use it since we had already purchased it. This added a significant amount of time to the overall priming step. I think most of the builders in our local EAA chapter did NOT use the PreKote and their priming turned out fine.

Once we had all the parts cleaned and dry, we donned our respirators and I put on the Tyvek paint suit. Jen handled moving the parts and ensuring that the coverage was good. I've sprayed paint before with both airless and HVLP sprayers, and I'm good with that, but hate the clean up part. However, I found that the clean up of the P60G2 was fairly easy with laquer thinner.